omegaaddict.com

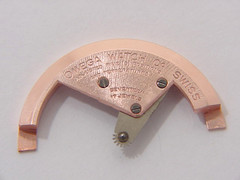

Was not quite sure where to start on this project. Started with good guesses, I thought. Turned out to be a bit more of a project to figure out than I had imagined.

The first several attempts with the use of too much copper in the mix would quickly patina. I would end up with a part looking far worse than when I started, almost like a well-aged penny.

I searched for counsel of plating experts. I thought for sure they could help. Turns out not so much. Most had no idea why I would want such a mix of metals and had never tried such a thing. It was back to the drawing board. I was sure rhodium could help; hard, bright, and with a touch of copper. I tried again with another mix. Looked amazing for a few weeks but the copper in the plating eventually succumbed to its usual patina. I put this project on the shelf a while, the question still on my mind.

One day I was talking to a coin collector. We got on the subject of plating. He tells me right out, “Kugerand! That's what you need.” A Kugerand is a beautiful and highly collectible African coin consisting of 91.67% gold and 8.33% copper. Interesting mix of metals to be sure! I started out again using a similar mix a lot closer to the Kugerand than I had tried before. Having a look at other coins I kept on experimenting with batch after batch till I got it down. Now I can get a nice color that holds up well with time.

Sorry can't tell you what I ended up with, that is a proprietary secret! My conclusion is that restoring the plating on Omega parts in this way is very time consuming and expensive to be sure. Plating is not essential to the functionality/running of a movement. Nice touch though when needed. Most parts are available if you take the time to look. Much easier to replace than restore a part. On a rare watch where a part can’t not be found and the parts is still functioning a restoration is in order.

A challenge I have enjoyed!!

No comments:

Post a Comment